Advancing Chemical Technologies

for Semiconductors, Clean Energy

& Life Sciences.

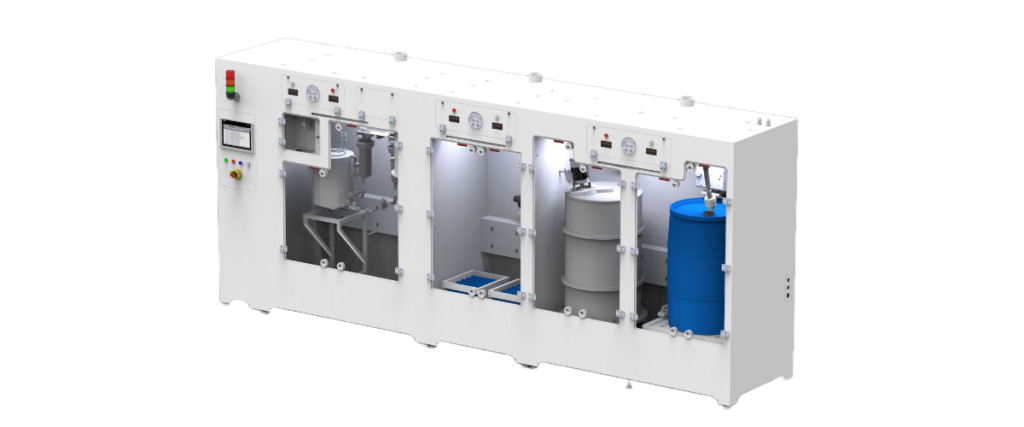

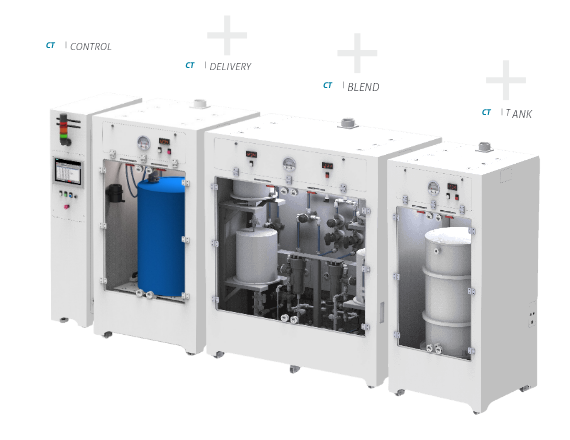

FAST CHEMTECH slurry blending & delivery systems, unlike anything else available on the market today, allow our customers to configure and design their slurry delivery systems according to their individual process and factory requirements. The systems are designed to accurately blend and deliver CMP and Polishing slurries to the point of consumption from any type of source container and with full redundancy, and metrology if required. The modular configuration allows for standardisation in the control but the ability and reconfigure should their process or volume demand change through the product lifecycle. Modules can be located in any configuration to accommodate various space and facility constraints.

FAST CHEMTECH systems are designed for demanding slurry blending and delivery applications where ultra-pure and safe processing will ensure the highest yield.

Our systems offer:

• A configurable range (for various abrasive types, all consumptions and all budgets)

• A modular concept that can be adapted to your customer needs

• High reliability

• Low shear force pumps

• Integrated metrology options

• Easy maintenance (user-friendly software, settings, etc.)

• Over 20 years’ experience

CT | CONTROL

These modules incorporate a centralized means to corral the electrical and control components for the CT Modular series helping optimize the entire process, enhance safety, increase uptime and ensure blend and delivery stability.

It uses standard off the shelf components and an industrial PLC and HMI control displaying the system PI&D status, with user friendly input and output screens, recipe selection, along with alarm logging etc. The system can collect Key Input Process Variables e.g. Density, Concentration, Flow etc. that allows engineers to have full visibility of their process.

CT | DELIVERY MODULES

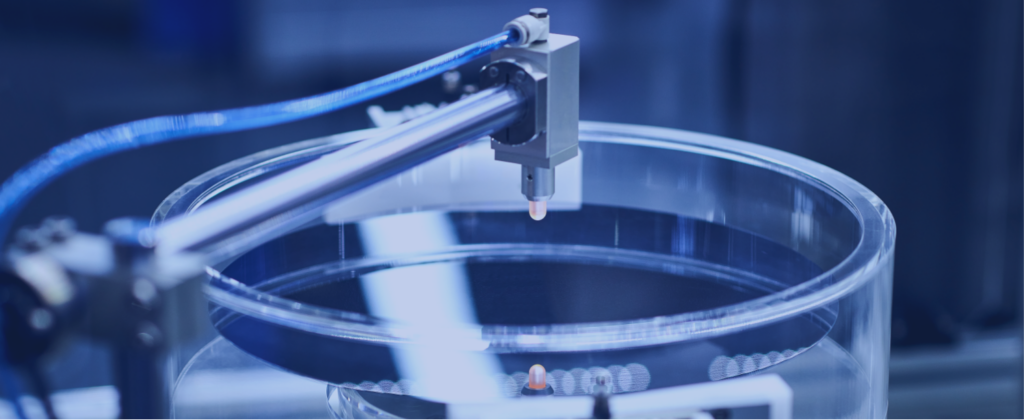

CT | DELIVERY Modules allow the automatic distribution slurries and acids, from totes and drums to the Points-of-Use (POU), or to the blending and day tank modules using controlled pumping. The design philosophy aims to achieve high uptime and reliability through the use of multiple back-up modes, and the various modular layouts with easy interchangeability allowing the end user to swap format easily without having to replace the complete system. A truly flexible system that can meet your changing production needs. Pre-mix sequences and the Variable Speed InDRUM mixing technology offer superior mixing and blending processing performance for slurry applications.

CT | BLEND MODULES

The various CT | BLEND Modules provide medium provide medium to large volume chemical blending capability suitable for standard polishing and CMP applications. The system uses weight-based blending. The blend tank is mounted on a scale and the constituents are added sequentially as required. A low shear maglev pump is used to homogenize the mix, that can be validated with various metrology options.

Various PH control and spiking options are also available to be incorporated into the system, with Humidified N2 to minimise drying out and agglomeration of slurry particulates within the mixing vessels.

CT | TANK MODULES

FAST CHEMTECH CT | TANK solutions offer multiple capacity and redundancy options that pair with the blending and delivery systems to provide continuous flow and pressure to the various processing systems within the fab.

Interested in ChemTech?

Discover more about our Blending, Collection & Delivery Solutions for Chemicals and Solvents.